- Via Seradello 223/A

Ponte Zanano (BS) Italy - (+39) 030 8911700

info@mollificiobrescia.it

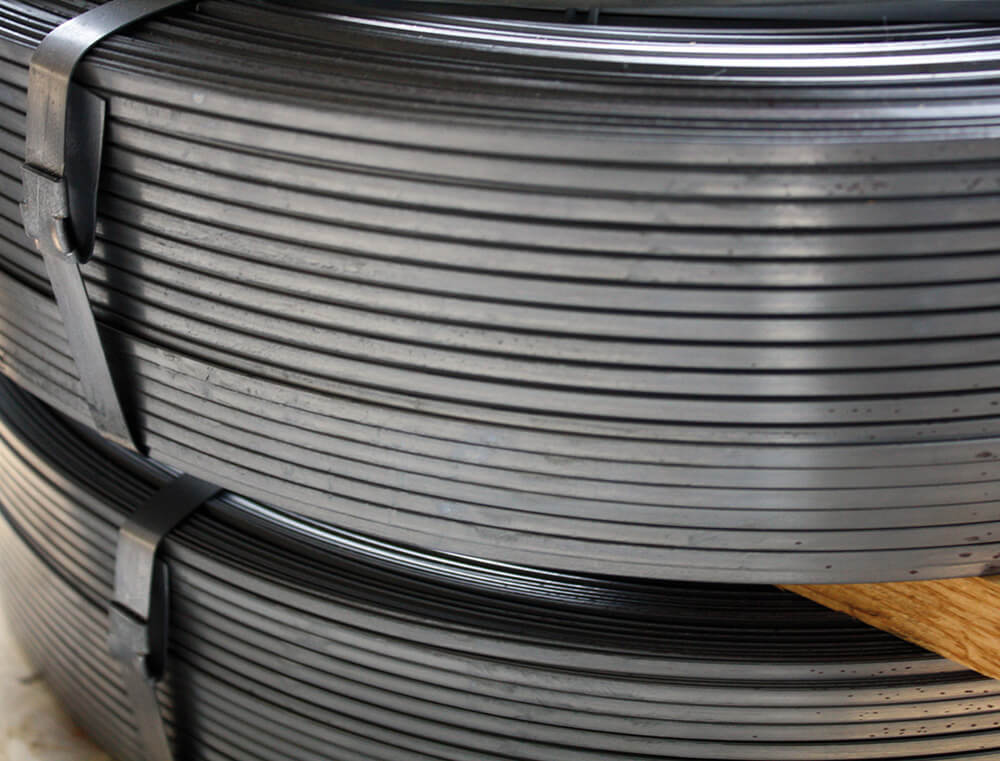

Mollificio Brescia pays special attention to the type of materials suggested to the customer during the design support phase, based on the use and environment in which the spring is destined. For this reason the company has a wide range of types of raw materials in stock and qualified suppliers at its disposal.

The most commonly used materials are:

Thanks to our qualified network of suppliers we can offer our customers surface finishes such as:

We are always looking for new materials and solutions so as to create new products or improve existing ones.

We maintain a high standard of quality by ensuring constant monitoring of all batch production cycles. We carry out fatigue, tensile and compression tests, 2D measurements with cameras and torque transducers.

We constantly invest in technologically advanced machinery staying one step ahead of market demands. We have introduced an industry 4.0 system and collaborative robots.